Infrastructure

- 900 Ton Extrusion Press

- Automated billet loading and handling system

- Advanced pressure and temperature control systems

- Extrusion of complex aluminium profiles

- High-speed production with precise dimensional control

EXTRUSION PRESS 900 TONS

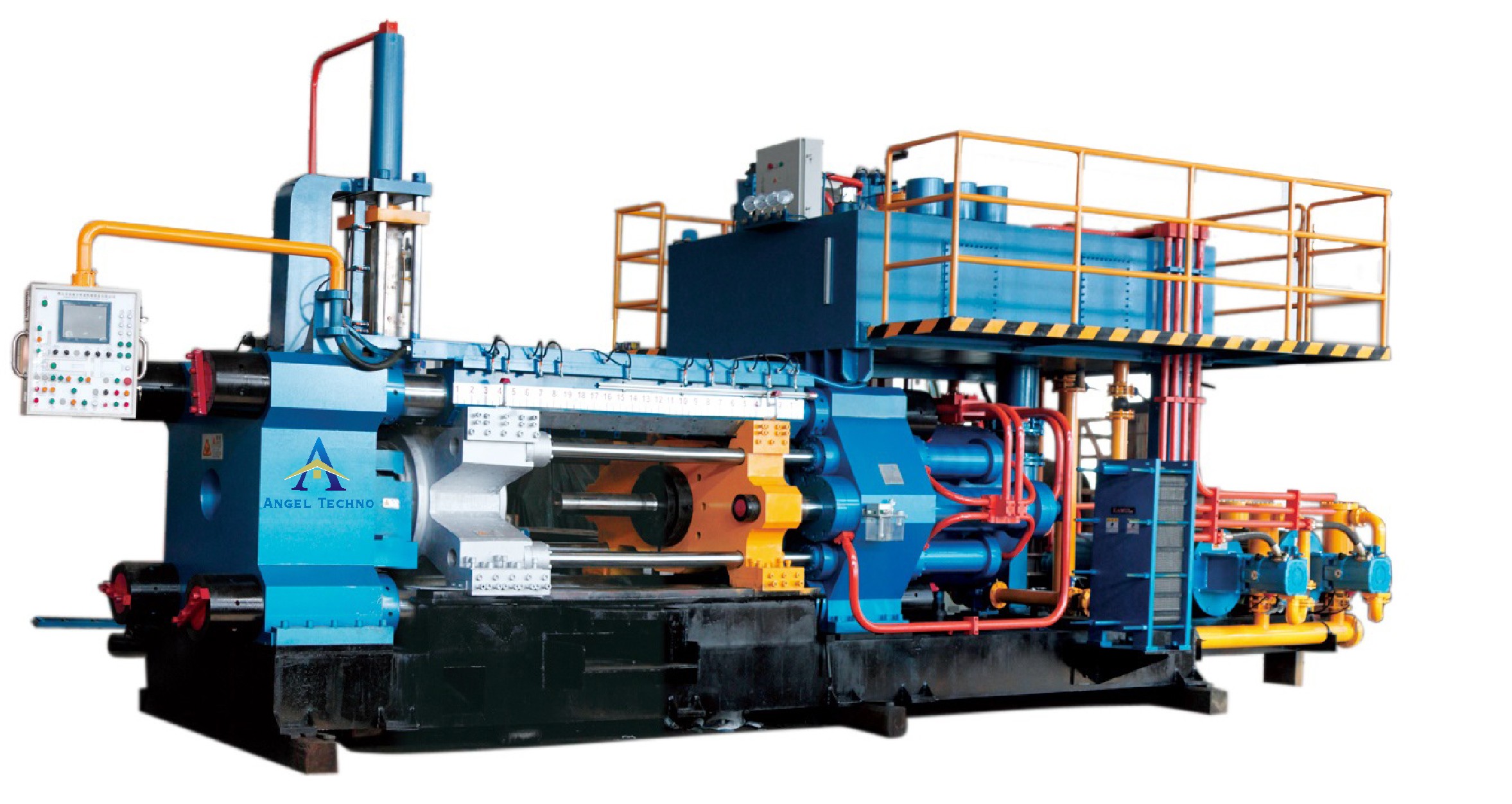

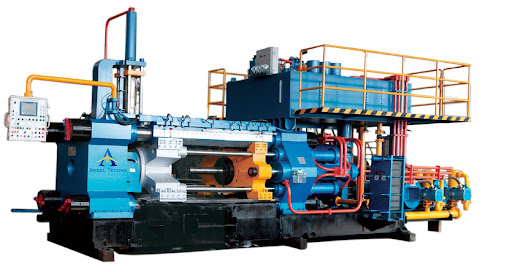

- 1800 Ton Extrusion Press

- Automated billet loading and handling system

- Advanced pressure and temperature control systems

- Extrusion of large and complex aluminium profiles

- High-speed production with precise dimensional control

EXTRUSION PRESS 1800 TONS

- Powder Coating Booths: 2 automatic powder coating booths.

- Oven Capacity: 3 x 23 m long oven with a temperature range of 180°C to 200°C

- Pre-Treatment: 7-stage pre-treatment process for ensuring a high-quality finish

- Quality Control: Equipped with advanced quality control measures, gloss meters, thickness gauges

Powder Coating Unit

- 2 x CNG-fired furnaces

- Capacity: 10,000 MT per annum

- Automated quenching system for rapid cooling

- Advanced temperature control and exhaust systems

- Comprehensive safety features

Furnace

- CNC machining centers

- EDM machines

- Grinding machines

- Lathes and milling machines

- Precision measuring instruments

Die Workshop

- 2 Aging ovens with temperature range of 150°C to 250°C

- Automated temperature control and monitoring systems

- Advanced humidity control systems

Aging ovens

- Automated cooling tables with controlled temperature and humidity

- High-speed cooling fans for efficient heat dissipation

- Advanced temperature monitoring and control systems

Cooling Table

- 20 ft long anodizing tanks

- Temperature control and cooling systems

- Wastewater treatment and recycling facilities

Anodizing Plant